Automated Winder

Developed as a side project to support my graduate research, this automated winder addresses the challenge of consistently winding pre-impregnated fiber ("pre-preg") from a variable-speed production line. The winder maintains consistent material tension by controlling the winding speed by keeping a constant position of the tensioning arm, ensuring tightly and consistently wound rolls. I was responsible for the complete lifecycle of this project, including design, programming, and manufacturing, resulting in a successful solution for winding pre-preg onto bobbins.

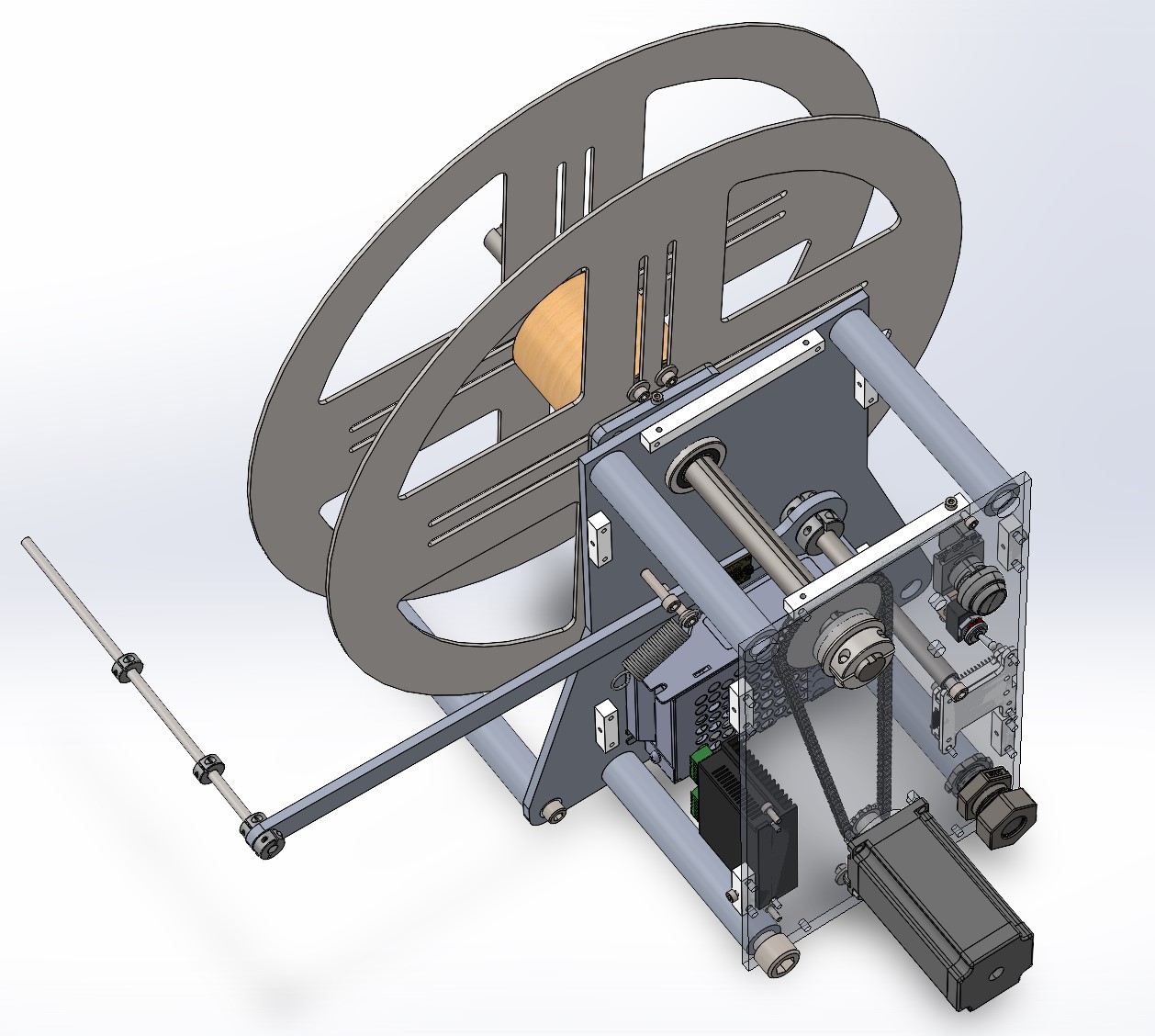

Figure 1: Automated Winder CAD

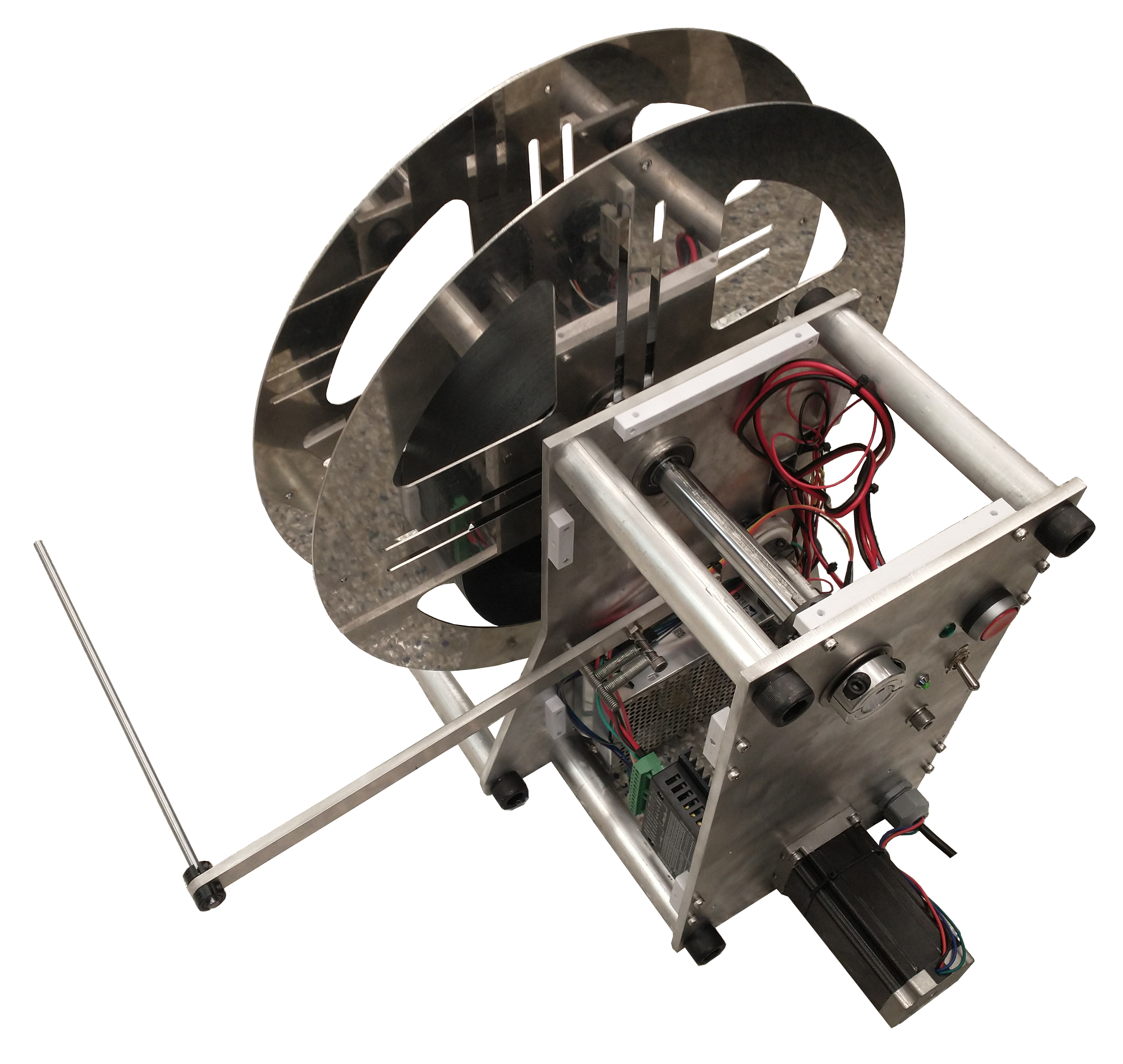

Figure 2: Automated Winder Opened

Design Highlights

- Cost-Effective Manufacturing: Primarily designed with 2D parts, enabling cost-effective manufacturing leveraging waterjet cutting

- High-Torque Winding: Utilizes a stepper motor with a chain drive to provide high torque, ensuring tightly wound bobbins and easy speed control

- Tension Control System: Employs an angle measurement sensor (gyroscope) to determine the tensioning arm's angle. This data is used to maintain consistent material tension during the winding process

- Microcontroller-Based Control: Uses an ESP32 microcontroller to dynamically adjust the winding speed based on the tension arm angle, ensuring consistent winding tension

- User-Friendly Interface: Features a simple start and stop button with an LED indicator to clearly display the operational status of the winder

Figure 3: Video of winder in operation