Automated Bushing Feeder

As part of my graduate research, I designed, manufactured, and programmed an automated bushing feeder. This device streamlines robotic manufacturing by automatically supplying bushings upon receiving input signals, eliminating manual placement, and significantly boosting efficiency.

Key Features and Contributions

- Automated Feeding Mechanism: Designed a robust system to consistently singulate and deliver bushings upon external triggers.

- Custom Manufacturing: Managed the fabrication of all feeder components, achieving tight tolerances and reliable performance.

- Integrated Programming: Developed control software to manage the feed sequence, process input signals, and ensure seamless integration with robotic systems.

- Improved Efficiency: Implementation in a robotic cell reduced cycle time and increased overall manufacturing throughput.

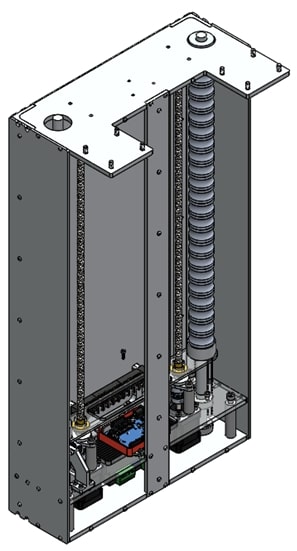

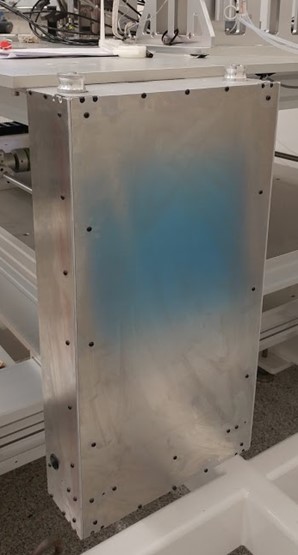

Figure 1 presents a CAD model of the feeder, while Figure 2 shows the completed project.

Figure 1: Bushing Feeder CAD Model

Figure 2: Completed Bushing Feeder

Design and Internal Components

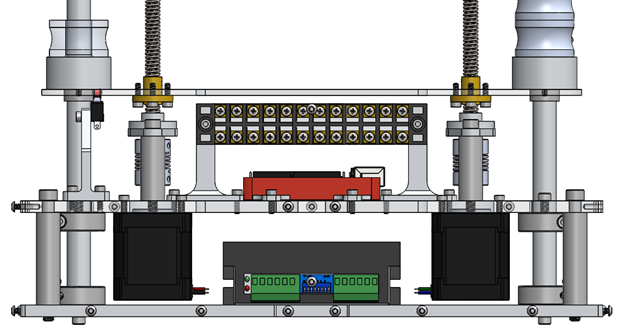

The automated bushing feeder was engineered to be cost-effective and easy to manufacture. Key internal components, as shown in Figure 3, include:

- Stepper motors

- Stepper driver

- ACME screw

- Limit switch for bottom indexing position

Figure 3: Internal View of the Bushing Feeder